Project Overview

The main goal of this

project is to present a design that is approachable by all. This

means it needs to be as simple as possible, built from

readily-available materials, using simple fabrication techniques, and

it must be low-cost. A bit lower on the priorities list is that it

too must be easy to operate and maintain, and must produce useful

output in reasonable quantities.

Biomass conversion techniques

involve large volumes and high temperatures. By its very nature then,

this project will involve metal fabrication, both sheet metal and

machining. The parts will not be complicated, though, so if you

cannot make them yourself, you should no have to go far to have them

made.

After reviewing the field, I have settled on a

thermochemical process called fast pyrolysis, which, its simplest

terms:

"Fast pyrolysis is a

high temperature process in which biomass is rapidly heated in the

absense of oxygen. As a result it decomposes to generate mostly

vapors and aerosols and some charcoal. After cooling and

condensation, a dark brown mobile liquid is formed,which has a

heating value about half that of conventional fuel oil."

('Fast

Pyrolysis of Biomass: A Handbook' A. Bridgewater ISBN:

1872691072)

OK. Fast. How fast? According to the sources I have read (ToDo:

Bibliography), the whole process needs to be done on the order of a

couple of seconds. That is, heating up the biomass to over 500C, and

cooling the resultant vapors and aerosols to condense them in 2

seconds. About the best way I can think to do this is by using a

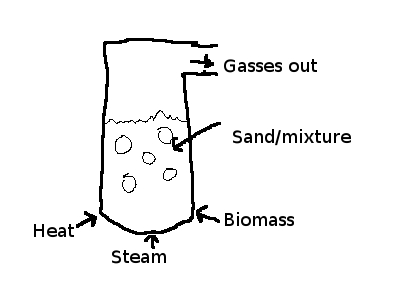

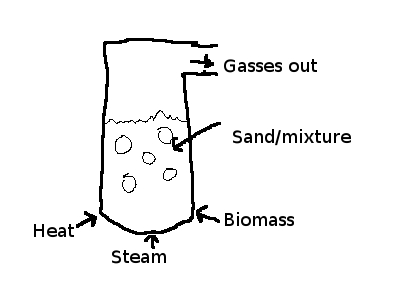

fluidized-bed reactor (Figure 1)

As

can be seen, a fluidized bed is a container filled with small

particles, (often sand, but can be any high-temperature small-scale

mixture) into which heat, biomass and sometimes steam are introduced.

Details of my thoughts for the reactor chamber can be found here.

The biomass is rapidly heated in such an environment, and turns to

gases and aerosols (entrained liquid in gas). In fast pyrolysis,

these product gases are rapidly cooled upon exiting the reactor.

These gases, upon cooling, condense to a mixture of various

compounds:

“The liquid contains

several hundred different chemicals in widely varying proportions,

ranging from formaldehyde and acetic acid to complex high molecular

weight phenols, anhydrosugars and other oligosaccharides.”

Further, large fractions of the product are problematic. The

product (by weight) is 10-15% Acetic acid, and 20-30% water.

The interesting thing (perhaps the perplexing thing) about this

product, is that:

“Pyrolysis

liquids cannot be completely vaporised once they have been recovered

from the vapour phase. If the liquid is heated to 100ºC or more

to try to remove water or distil off lighter fractions, it rapidly

reacts and eventually produces a solid residue of around 50wt% of the

original liquid and some distillate containing volatile organic

compounds and water.”

Hmmm, actually quite perplexing, for most methods of

separation/processing involve raising the temperature of the process

to facilitate any reaction. OK, I propose:

Do all post-creation processing of the the bio-gas while it is

still a gas

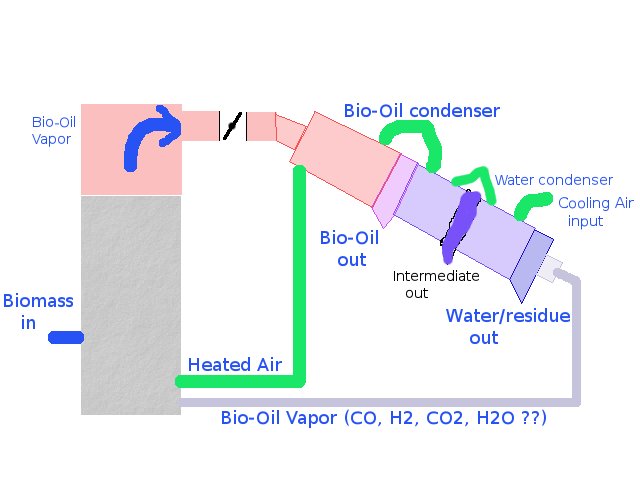

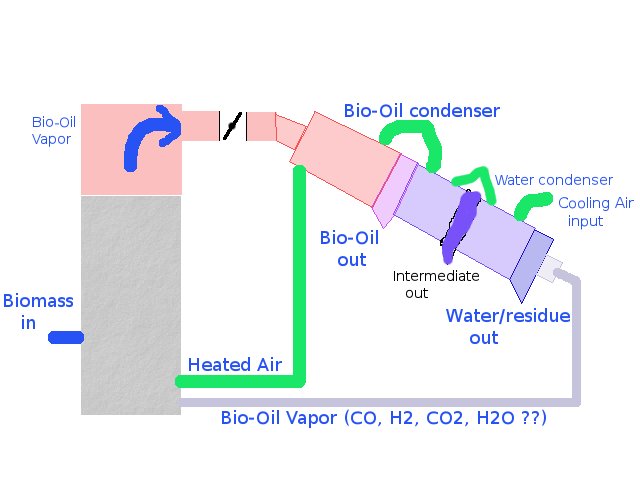

I propose, at the very least, a fractional condensation of

the product gases, meaning, cooling rapidly to the liquid point of

the first sought-after product. In the case of bio-oil, this would be

down to near the point of condensing acetic acid, around 118C,

or 140C for acetol, then down to just above 100C, to capture product

above water's boiling point, then finally 90C or so, to capture

water. The gases remaining can be re-introduced to the reactor.

Perhaps a picture will help (also see the Mechanical design page

here:

The aforementioned idea could be used to yield a highly dense

(little water present) biomass derivative, that could be titrated

with alcohols to produce a heating or transportation fuel.

This idea can be extended in both directions from the disclosed

temperature range for condensation.

If between the reactor and the first stage of condensation,

sensible heat, electromagnetic energy (light, UV, microwave), or

mechanical (in the form of ultrasound or other macro-molecular wave

phenomenon) is added to the product gas, many reactions are

possible, from steam reformation to large molecule cracking.

If the last stage is further refined, alcohols could be

stripped from the product stream, and the non-condensible gases

captured and put to use rather than recycle.

Revision : 30 Date: 2006/07/13 21:52:07